Rentals

Fusion Machines: 2LC | Pit Bull® 14 | Pit Bull® 26 | McElroy 28 | McElroy 412 | TracStar® 618 | TracStar® 500 | TracStar® 630 | TracStar® 900 | MegaMc™ 2065 | Electrofusion processor

Accessories: DataLogger Vault | DataLogger 6 | DataLogger 5 | PolyHorse | PowerAssist | MegaMc PolyHorse | Pipe Rollers | Electrofusion Scraper | Portable Generator | Pipe Stand | Infield Tensile Tester | Test Caps

Machines

2LC

1/2″ CTS – 2″ IPS (16mm – 60mm)

The 2LC employs a semi-automatic locking cam (LC) system to maintain force during the cooling cycle. It incorporates McElroy’s patented Centerline Guidance System and is designed to but, fuse tees, ells and other fittings.

The machine is made primarily of surface-hardened aluminum for light weight and durability. The jaws and inserts have multiple serrations for maximum grip on the pipe.

Pit Bull® 14

1″ IPS – 4″ DIPS (32mm – 110mm)

The McElroy Pit Bull 14 is a compact, lightweight, highly reliable and rugged machine. The machine incorporates McElroy’s patented Centerline Guidance System, and is designed to butt fuse tees, ells and other fittings with consistent, high-quality results. With the semi-automatic locking cam, the Pit Bull 14 locks the movable jaw in place during the cooling cycle.

Features include reversible jaws, clamp knobs and facer. Add the optional 4-wheel cart with outrigger pipe supports or a manual fusion machine stand that raises the machine to a comfortable working level.

Pit Bull® 26

2” IPS – 6” DIPS (63mm – 180mm)

The Pit Bull 26 incorporates McElroy’s patented Centerline Guidance System and is capable of butt fusing tees, ells and other fittings. The machine has a semi-automatic locking cam that locks the movable jaw in place during the cooling cycle. An electric facer offers fast, efficient facing with an advanced blade design for smooth face offs and longer life.

McElroy 28

2″ IPS – 8″ DIPS (63mm – 225mm)

The Rolling 28 has staked its claim as the industry standard for more than 40 years. Its ease of use and rugged quality construction opened the door for the most extensive line of 8-inch fusion machines on the market.

The Rolling 28 can also be ordered as a Combination Unit (CU) that allows fusion of branch saddles.

McElroy 412

4″ IPS – 12″ DIPS (110mm – 340mm)

McElroy’s Rolling 412 changed the industry when it was introduced as the first fully self-contained fusion machine in the world. Today, the 412 can be ordered with gas or electric power on a wheeled chassis that offers easy, on-site maneuvering. A hydraulic-clamping option is also available.

TracStar® 618

6″ IPS – 18″ OD (160mm – 450mm)

The new TracStar 618 Series 2 has been completely redesigned based on feedback from the field. The Series 2 machines incorporate a new cowling design that aids in heat dissipation — while providing easier access for machine maintenance. An updated electrical system increases the circuit protection and a standard battery disconnect in now incorporated for easy lockout.

The TracStar 618 is also available as an Automated machine that guides the operator through each step of the fusion process.

TracStar® 500

6″ IPS – 20″ OD (160mm – 500mm)

The TracStar 500 was the first fusion machine in the world to be mounted on a track system, making it mobile in almost any terrain. Considered the flagship of McElroy machines, its success spawned the entire TracStar line of fusion equipment. The TracStar 500 Series 3 adds additional productivity enhancing features, such as indexer-mounted facer and heater that are powered by the machine, standard Hydraulic Clamping, dual pipe lifts and an economy engine throttle setting to conserve fuel.The TracStar 500 Series 3 Automatic is also available when automatic control and monitoring over the heat, soak, fuse and cool cycles is required.

TracStar® 630

8″ IPS – 24″ OD (225mm – 630mm)

The self-contained machine eliminates the need for a separate power source on the job site. An on-board generator powers the heater while powerful hydraulics assist all fusion functions, including the operation of the jaws, pipe lifts and facer. Models are available with advanced emission control technology that meets the EPA’s latest Tier 4 standards, without the need for diesel exhaust fluid (DEF). The TracStar 630 Series 2 is also available as an Auto unit that controls and monitors the heat, soak, fuse and cool cycles.

TracStar® 900

12″ IPS – 36″ OD (340mm – 900mm)

The TracStar 900 is a self-contained, self-propelled, all-terrain fusion machine with an on-board generator for powering the heater. The carriage can be easily removed for in-ditch use.

Also available is the Automatic TracStar 900 that controls and monitors the heat, soak, fuse and cool cycles. It has a built-in data logging feature that keeps a record of each fusion joint, which allows you to verify joint integrity.

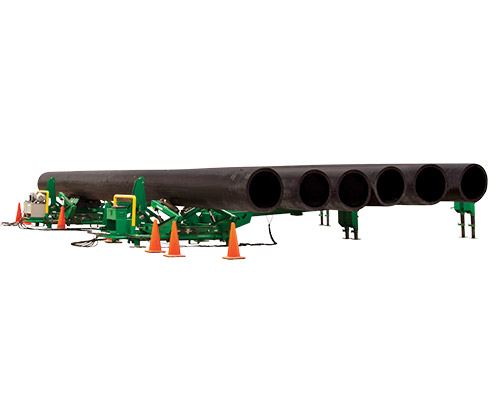

MegaMc™ 2065

20″ OD – 65″ OD (500mm – 1600mm)

Made for the largest of pipe applications, the MegaMc 2065 has been used around the world as large-diameter polyethylene pipeline projects grow in every industry.

It allows for butt fusion of most fittings without special holders. Mitered inserts are available for fabricating ells. McElroy’s unique semi-automatic control system requires only one operator. Hydraulic power assists all fusion functions including the complete operation of the jaws, pipe lifts, heater and facer.

Electrofusion processor

Electrofusion is a method for bonding HDPE pipe using heat from energized wire within a coupling. An alternative to butt fusion, electrofusion is cost-effective and ideal for repairs and a range of applications – tie-in of directional drills, manhole connections, confined space repair, branch saddles and more.

IMSCO has an extensive range of Electrofuse fittings in stock. We have processors and scrapers in our rental fleet ready for your project.

Accessories

DataLogger 6

The DataLogger 6 captures the most important data from your fusion job site to ensure that a joint was fused with the correct pressure and times according to supported standards. The ruggedized, Android-powered tablet records and documents key parameters of the fusion process including heat soak times, heating pressure, open/close times, fusion time, fusion pressure and cool time. A real-time graph gives the operator immediate visual feedback and information regarding the integrity of each fusion joint.

Joint records from the DataLogger 6 can be securely stored and analyzed online in the DataLogger Vault™ – allowing quick and easy sorting, tagging and sharing of joint records by machine, joint, operator, device or job.

DataLogger 5

Engineers, pipeline owners and contractors are quickly recognizing the importance of documenting the pipe fusion process. Not only does it provide for increased accountability, but it can be a comprehensive, archival record of the entire job.

The DataLogger 5 from McElroy captures information relevant to your job such as GPS locations, jobsite photos and barcoded details from pipe and fittings along with the ability to upload the collected data from the field via wireless connections to the DataLogger® Vault™.

DataLogger Vault

The need for better record keeping and increased accountability is growing among those who build and manage pipeline infrastructures. New standards, including ASTM F3124, have been implemented to govern the collection of data from plastic pipe fusions. The new DataLogger® 6 from McElroy meets these requirements by capturing the most important information related to fusion operations. It is now easier than ever before to add improved traceability and a higher level of assurance that pipelines were fused properly before they go into service.

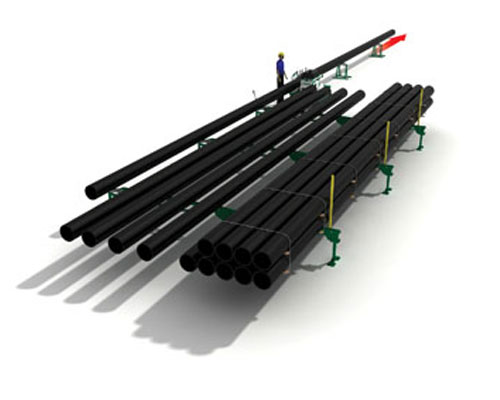

PolyHorse

The PolyHorse is a pipe-handling system that consists of a series of adjustable racks to store and help install pipe on the job site. The PolyHorse can reduce manpower expense, provide an efficient, less hazardous environment for handling pipe bundles and enhance productivity by 150%.

PE pipe is off-loaded from the delivery truck directly onto the PolyHorse where it is off the ground and out of the way until needed. The operator rolls the pipe down the rack and onto the integral pipe rollers where it is easily loaded into a McElroy fusion machine. This eliminates the costs for additional lifting equipment and manpower.

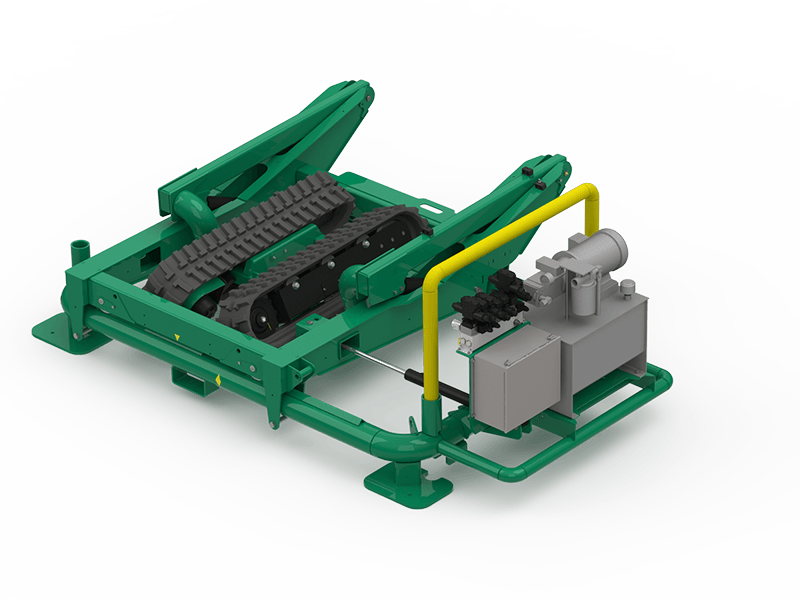

PowerAssist

The PolyHorse is a more productive way to store and handle pipe on the job. It helps to reduce manpower and expenses while promoting a safer working environment. The PolyHorse pipe-handling system is a series of adjustable racks available in two size ranges: The standard PolyHorse®, for 3” IPS to 20” OD (90mm to 500mm) or the MegaMc® PolyHorse®, for larger size pipe from 20” OD to 48” OD (500mm to 1200mm). They are designed to hold enough pipe for a day’s worth of fusion work and allow a single operator to load and align pipe without the use of extra machinery.

MegaMc PolyHorse

The PolyHorse is a pipe-handling system that consists of a series of adjustable racks to store and help install pipe on the job site. The PolyHorse can reduce manpower expense, provide an efficient, less hazardous environment for handling pipe bundles and enhance productivity by 150%.

PE pipe is off-loaded from the delivery truck directly onto the PolyHorse where it is off the ground and out of the way until needed. The operator rolls the pipe down the rack and onto the integral pipe rollers where it is easily loaded into a McElroy fusion machine. This eliminates the costs for additional lifting equipment and manpower.

Pipe Rollers

McElroy offers Low Profile Rollers for use with a range of pipe from 4” to 2000mm. McElroy rollers allow you to pull a string of thermoplastic pipe around a curve and over considerable distances. Pipe and the fusion joints slide easily through the rollers and stay off the ground, keeping the pipe clean, reducing damage and increasing productivity.

Pipe Stand

Pipe stands save wear and tear on machinery, reduce strain on operators and makes the fusion process easier. They’re adjustable for uneven terrain so that the pipe is supported at the same height as the machine. By bringing the pipe in parallel to the machine it is much easier to adjust hi/low and achieve a square face-off.

Pipe stands can greatly increase productivity. Instead of moving the machine for each joint, fused pipe can be pulled through the machine allowing a new stick to be rolled in for fusion. This allows all the pipe to be staged in one location keeping the fusion machine stationary, minimizing down time between fusion joints.

Electrofusion Scrapers

The most important step in the Electrofusion process is prepping your pipe with the right tools. Please contact us for more information on which tool is right for you.

Portable Generator

Rental units are available to get your fusion jobsite up and running. Our generators are perfectly matched to run the smaller fusion equipment.

Infield Tensile Tester

The In Field Tensile Tester provides a quick and easy way to qualitatively test fusion joints in the field. Dual reduced section coupons allow for quick comparisons between integrity of the joint and the parent pipe. A hand-pump system tests coupons from 2” IPS and larger pipes (up to 5” thick wall).

Test Caps

McElroy Test Caps are designed for quick and easy air pressure testing of polyethylene pipe. All of our test caps are reusable, provide a positive o-ring seal and have been pressure rated to 165 PSI to meet 49 CFR192.513. Installation and removal is quick and easy on pipe sizes from ½” CTS – 2” IPS and 32mm – 63mm branches. Test pressure actually improves the cap’s grip on the pipe. One test cap is required per pipe size. They are made of corrosion-resistant material and are durable in construction.